The Powertrain Story

The new ‘heart’ of the Perodua Kembara DVVT is the highlight of the model and it scores a couple of ‘firsts’ in the Malaysian locally-assembled vehicle context. It’s the first 1.3-litre engine with variable valve timing – the ‘in-thing’ in today’s engines – and it’s also the most powerful 1.3-litre engine ever offered.

The engine is a relatively new one developed by Daihatsu Motor, Perodua’s technical partner and shareholder, which also provided its Terios model for adaptation to the Kembara. Coded ‘K3-VE’, this 4-cylinder engine also has a 1.3-litre displacement but is 2 cc more than the old engine (HC-EJ).

|

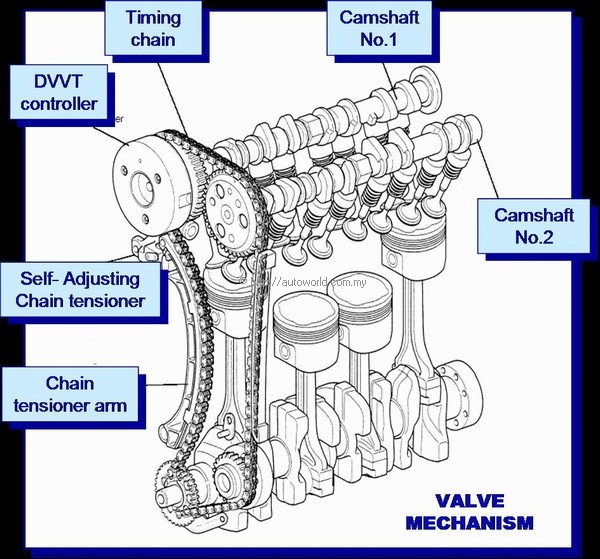

The K3-VE is not just the old engine with a new cylinder head but is an entirely new powerplant. Where the old engine was a fast-revving oversquare type (short-stroke), the new one is an under-square type (longer stroke) which means better low-end torque. The aluminium cylinder head area is also very different with an extra camshaft and four valves per cylinder. It now uses a more durable single chain drive to operate the camshafts, instead of the belt drive before which was operating a single camshaft. A self-adjusting tensioner ensures that the chain is always kept taut.

The variable valve timing mechanism is called Dynamic Variable Valve Timing (DVVT) and it varies the opening/closing times of the eight intake valves. The system is electronically-controlled and makes variations almost instantaneously in a seamless manner, optimizing the flow of the air-fuel mixture into the combustion chambers. To determine when and what variations are need, the engine management system gets data from at least five sensors (one of which also monitors the temperature of the engine coolant). It then analyses this data and chooses the right opening/closing time for the given driving condition – all within milliseconds.

The system is similar to that used on the Toyota Corolla Altis and Camry (in fact, it comes from Denso, the same supplier as well) and can also be found in the Mitsubishi MIVEC engine, Volvo S60/S80, BMW VANOS engines and the Honda i-VTEC engines.

How effective is DVVT? Very – as the power and torque increases show. Power output is now 63 kW (85.7 bhp) at 6000 rpm, 3.3% more than before and close to the figure for the Honda City’s 1.5-litre engine (88 bhp). Torque is up by an impressive 14.3% to 105 Nm and it peaks at just 3200 rpm which is 1900 rpm lower than before. This latter point demonstrates the value of a variable mechanism because in the past, the engineers had to decide on just one state of tune and practical reasons dictated a higher torque figure. Now they can have the torque peak lower down where it is useful and still have a good spread over almost the entire rev range. Incidentally, the compression ratio is also boosted to 10:1 and this makes combustion more efficient.

|

Other features of the engine include a resin uniform-length intake manifold for smoother flow and an offset steel crankshaft (reduces friction). There are two drive belts, one to power the air-conditioner compressor, alternator and waterpump, and the other just for the power steering energizer. There is now one ignition coil per spark plug, whereas the old model had one coil for all four spark plugs, and the coils are directly managed by the ECU so there is no distributor needed.

A major benefit from DVVT is that toxic emissions in the exhaust gases are lowered a great deal and with the 3-way catalytic converter, pollution is almost nil. The very poisonous oxides of nitrogen, in particular, are lowered by 40% and all this is due to the much better and more complete combustion.

The complete combustion also enhances fuel economy although in driving terms, the lower fuel consumption also comes from having a better weight-to-power ratio. Perodua’s testing in Malaysia shows that the Kembara with DVVT and manual transmission is 12.02% more economical (12.58 kms/litre) while the automatic is 14.8% more economical (11.02 kms/litre). This testing was done on routes of between 270 kms and 300 kms with a mix of highway, country and urban driving conditions.

As for straightline performance, it would be expected that the new engine will give better figures than before. Factory claims for 0 – 100 km/h are 13.49 (MT) and 13.6 seconds (AT) which are 0.8 and 2.0 seconds better, respectively. Top-end performance also shows improvements of 7.3 km/h (AT) and 4 km/h (MT) with the manual version able to get up to 155.9 km/h while the automatic should hit 151 km/h.

There’s another aspect of the new engine which is also noteworthy and addresses one of the issues which owners had – noise levels. A lot of effort with into bringing this down and apart from engine features like an aluminium oil pan, there are also other parts of the car where noise suppression measures have been taken.

Perodua-supplied figures (which we are sure we can trust) indicate that compared to a Toyota Corolla Altis at a speed of 80 km/h, the Kembara DVVT cabin noise level is only 1.1 dBA higher (AT version) and compared to a Proton Wira 1.3 (AT), it is 2.6 dBA quieter. ; even against the Waja (AT), the difference is 1.9 dBA. The engine noise level of the Kembara DVVT (MT) is also low in comparison to the same models. The Corolla Altis engine is still quieter at 55.2 dBA while the Kembara DVVT (MT) is 56.6 dBA whereas the Waja (AT) is 58.7 dBA. To get some perspective on these numbers, here are the noise levels of some common situations: normal conversation is 60 dBA and a jet aircraft from about 30 metres away is 130 dBA.

While the manual transmission is the same unit (with only a change in the 1st gear ratio from 4.059 to 3.769, the clutch is changed to a hydraulic type, giving a better feel and better response to changes.

The automatic transmission is an entirely new unit with electronic controls. Most of the ratios are higher (numerically lower) but the final drive is still the same low ratio to ensure that zippiness is still maintained.

The automatic transmission is fully matched to the K3-VE engine and there’s an ‘auto-run mode’ which is said to be an intelligent sort of mode. The system monitors driving conditions and goes into either a power or economy shift program automatically. With electronic controls, the shifts will be smoother due to better interfacing between engine operation and changing of gears. There is also a feature called ‘anti-squat’ which is normally related to the suspension geometry but in this case, it seems to have something to do with the transmission of power along the driveline.

As before, drive goes to all four wheels all the time, so this is a full-time 4WD system but without high/low gear ranges. Variations in rotating speeds between the front and rear axles are handled by a centre differential which can also be locked manually. Locking the differential means that torque distribution is exactly 50:50 between front and rear wheels and is not for normal road use as it will cause unnecessary drag, resulting in more wear and tear. It is meant for the most difficult terrain conditions, particularly muddy conditions.