Ford plants cut water wastage globally

The recent water shortage fiasco that hit the Klang Valley region was a timely if painful reminder to Malaysians the preciousness of treated water and the importance minimizing waste. Although the majority of our planet’s surface is covered by water, only a small portion of that water is consumable, and treating water to a clean drinkable state requires considerable resources.

Yet, with population and industries growing apace, global consumption of water is only ever going to increase and the struggle is on to ensure a sustainable supply of clean water to meet future needs. Minimization of wastage is therefore important, and since 2000, Ford Motor Company has been strategically working to improve the company’s water impact globally in by setting year-over-year reduction targets as part of its Global Water Management Initiative.

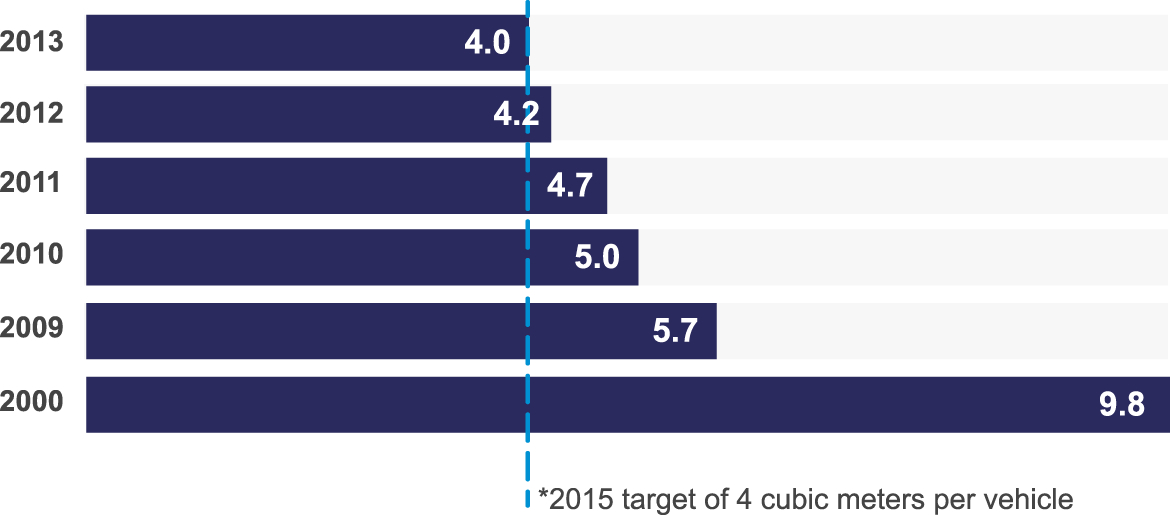

Efforts are now bearing fruit, with the company’s 15th Annual Sustainability Report released yesterday announcing that it successfully reduced consumption of water per vehicle manufactured by 30% measured from levels in 2009, reaching the goal two years ahead of schedule. Plans are under way to further cut water use by another 2% this year and to set new long-term goals.

“As Ford continues with its largest global expansion in more than 50 years, the company also recognises that working in regions struggling with water scarcity will soon make water a costly commodity,” said John Fleming, executive vice president, Global Manufacturing and Labor Affairs for Ford Motor Company.

Examples of Ford’s global water conservation efforts include Minimum Quantity Lubricant (MQL) process in the Changan Ford Engine Plant that managed to save over a million litres of water per year for a line rolling out 450,000 engines annually. Ford plants in India, Thailand and China use three-wet paint technology and rotated-entry dip paint technology to reduce water as well as energy and material use. In Chennai, India, Ford’s vehicle assembly and engine plant now recycles 100% of its wastewater, while in Chongqing, China, Ford’s two assembly plants recycle up to 378,000 litres of water every day.

Across its organization, Ford has managed to cut global water use by some 61%, close to 38 million litres (10 billion gallons), between 2000 and 2013. According to the US Environmental Agency, that is enough water to give 1 billion people a five-minute shower each.

Moving forward, Ford now aims to extend its water-saving initiatives to suppliers, by getting high water-use suppliers and those working in water-stressed regions to voluntarily report water consumption. Ford will then work with the suppliers to achieve reductions. The hope is that successful initiatives will be mirrored by other suppliers globally, helping Ford to significantly reduce its environmental footprint.

KON

Images: Official Ford release.