Mercedes-Benz Malaysia presents energy efficient vehicle roadmap

Being effectively the brand that invented motorized transport, Mercedes-Benz prides itself for being at the forefront of innovation, particularly in matters relating to powertrain development. Modern motoring requirements place an increasing emphasis on sustainability, which means new engines increasingly need to forge an intricate balance between performance and economy.

Whilst finer details may vary from region to region, the general trend in the automotive industry is heading towards reducing emissions and improving overall efficiency. In developed nations, these requirements are even enforced by law, with Europe being the prominent example that comes to mind. This trend is also guided by demands from consumers for more frugal vehicles – let’s face it, fuel is expensive, and will only get ever more so.

To meet these demands, European car makes have embraced engine downsizing to lower consumption, and marrying it with forced induction and direct injection to maintain potent outputs. Mercedes-Benz is in fact among the earliest adopters of this approach, starting with the 1.8-litre supercharged Kompressor engines which were then transformed into the newer turbocharged CGI mills that powered the C-Class and E-Class.

“Mercedes-Benz has a unique track record of countless technological innovations, outstanding design, visionary developments and triumphant victories, whether it be in comfort, safety, design or drive technology – we have set new standards in every area,” said Roland Folger, President of Mercedes-Benz Malaysia whilst speaking to the press earlier this week presenting Daimler-Benz’s Road to Emission-Free Driving long-term product plan.

Moving forward, Daimler-Benz believes that internal combustion engines as a whole will continue to form the backbone of our transport requirements. Due to logistical reasons – battery range and availability of charging facilities – electric vehicles are a long way from being viable replacements for the good old-fashioned stroke of a piston. The company believes that optimizing fuel consumption of combustion engines remain a key element on its long-term road map to emission free mobility.

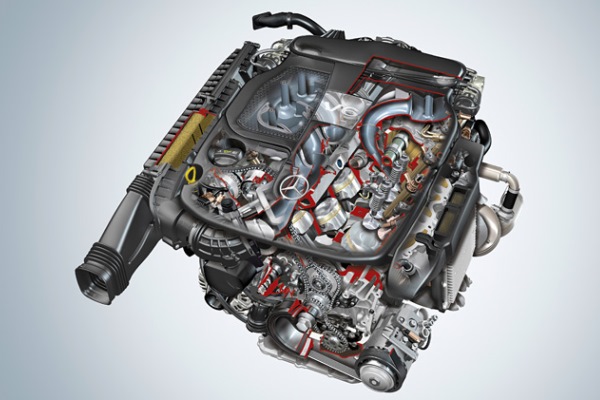

Daimler’s current portfolio of petrol and diesel combustion engines consist primarily of direct-injected powerplants available in four-cylinder, V6, and V8 configurations. These engines are equipped with the latest piezo direct injectors that are able to inject precisely-metered amounts of fuel at just the right moments of the combustion cycle. Complementing this ability is the multiple ignition system in which the plugs spark not just once, but possibly up to five times in a single stroke, enabling cleaner and more effective combustion.

In the latest Mercedes-Benz models, these advanced engines are paired with an in-house designed 7-speed automatic transmission dubbed the 7G-Tronic. Recently, a newer 9-speed transmission, called the 9G-Tronic, was introduced, and it was found that in the E 350 BlueTEC (a variant not officially sold in Malaysia), fuel consumption was reduced from 5.5 – 5.9 l/100km to 5.3 – 5.6 l/100km. Carbon dioxide emissions accordingly went down from 144 – 145 g/km to 138 – 148 g/km. Besides saving on fuel bills, such differences can potentially reduce annual road tax in countries that operate an emission-based taxation system.

Folger added that, “One important fact that I should bring to your attention is the definition of EEV, Energy Efficient Vehicles. EEVs are not limited to hybrids or electric vehicles but it is basically a good, technology-neutral definition of vehicles that through various means reduce carbon emissions.”

For the future, Daimler is working on a new engine design that seeks to combine the best characteristics of petrol and diesel engines into one powertrain, giving rise to the 1.8-litre Diesotto engine that was previewed in the F700 Concept car that debuted in the 2008 Frankfurt Motor Show. Armed with a two-stage turbocharger and paired with a 20hp hybrid module, the four-cylinder Diesotto engine makes an impressive 238hp and 400Nm whilst consuming fuel at a rate of 5.3 l/100km (CO2 – 127 g/km). It is a Euro 6 compliant engine.

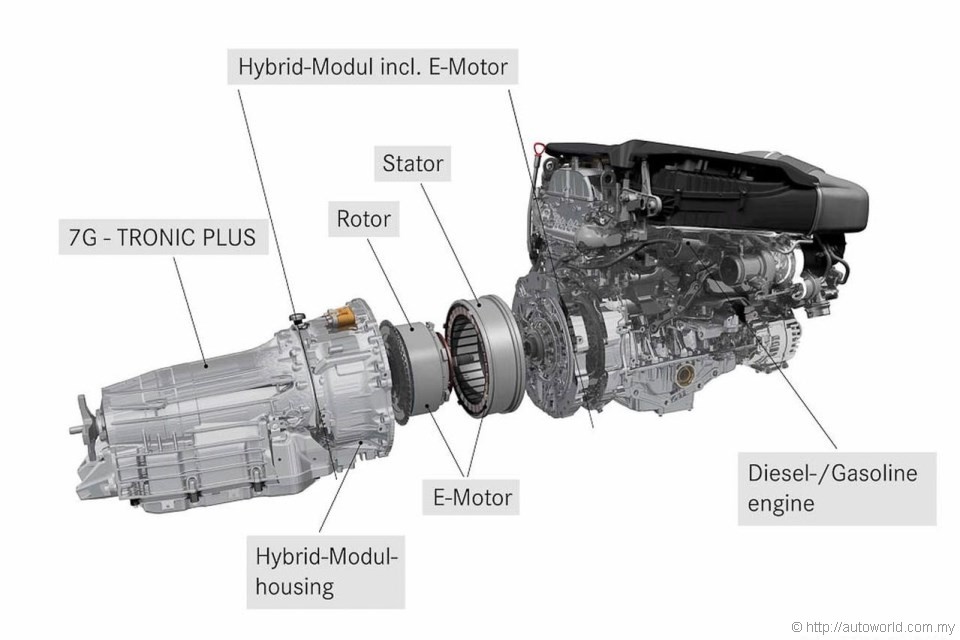

Also in place is a comprehensive modular hybrid architecture which allows Daimler to freely mix-and-match different batteries, hybrid modules, transmissions, and combustion engines to create a variety of hybrid packages to suit diferent needs. The portfolio features batteries and hybrid modules of various power ratings paired with petrol and diesel engines in both four-cylinder and V6 guises, albeit only for models with longitudinally-mounted engines. Models such as the A-Class and B-Class with transverse engines do not have hybrid powertrains available at the moment.

Complementing the hybrid engines are the plug-in hybrid derivatives, an example of which is the W222 S 500 Plug-In Hybrid introduced in this year’s IAA Frankfurt Motor Show. Its high-voltage lithium-ion battery can be recharged both on the move and from an external charging socket. With its battery fully charged, the 107hp / 340Nm electric motor is able to propel the S 500 Plug-In Hybrid on its own for 30km before the combustion engine needs to kick in.

Preparing for the distant future, Daimler is investing heavily in developing more advanced batteries for electric vehicles and propelling research in fuel cell technology. As of 2012, Daimler is the world’s first automotive manufacturer to develop and produce batteries in-house for automotive applications.

In the short term, however, all automotive manufacturers, including Daimler, are seeking to push the efficiency envelope of the combustion engine as much as possible to ensure global sustainability. Yet, the best efforts of auto makers are also dependent on having the supporting infrastructure in place to support the latest developments. Being a European manufacturer, Daimler’s engineering goals are primarily influenced by European emission and safety standards. Mercedes-Benz Commercial Vehicles, for example, recently launched a Euro 6 compliant truck in the European market.

Implemented since 1993, the European emission standards are now moving into its sixth iteration (Euro 6) which comes into force next year in stages depending on vehicle category. The successful implementation of these increasingly stringent standards require a two-pronged approach – clean engines that combust fuel more efficiently, and clean fuel available for combustion. Most European manufacturers, Daimler included, have the former in place, but the latter is the tricky bit.

As we all know, fuel in Malaysia today complies to Euro 2, a standard which fell into disuse even before the turn of the century. The promised implementation of Euro 4, itself still an outdated standard, has yet to come to fruition. This considerable discrepancy creates huge problems for automotive manufacturers in planning product life cycles for our market. Most modern European engines, tuned to run on clean Euro 5 – Euro 6 fuel, have to be readjusted to Euro 2 fuel before being exported to Malaysia, a scenario which creates a double whammy – besides causing the engines to lose their full economy potential, they also add developmental cost in having to create another unnecessary engineering variation. Behind the scenes, some European manufacturers put Malaysia into the ‘dirty fuel’ category in their internal classifications.

Folger emphasized this particular point in his closing speech, saying that, “We see tremendous benefits for Malaysia to catch up in terms of diesel quality. As the gap is significantly widening between Malaysia and Europe, it is not just beneficial, but vital that we narrow the gap if we want to move towards the direction of sustainable vehicles. This, complemented with the proper tax structure, will certainly bode well for Malaysia.”

Since 2011, the Government has been trying to promote the usage of hybrid vehicles by means of tax incentives which help lower prices considerably thus making them affordable to a greater segment of the public. The incentives, which apply only to sub-2,000cc hybrid vehicles, are scheduled to lapse at the end of this year, but the recently-presented national budget of 2014 was deafeningly silent about the continuation or discontinuation of these incentives. Many industry players are calling for an extension of the incentives with a more extensive definition of energy efficient vehicles – preferably one rated based on the vehicle’s energy (fuel) consumption rather than a simplistic classification based on engine size.

“The application of a proper infrastructure will enable Malaysia to become an automotive hub for high quality vehicles and also create a cleaner environment. We believe that this is a very specific aspect that could propel Malaysia several steps ahead of neighbouring countries. The combination of these measures should ultimately promote a fair, transparent and level playing field to ensure Malaysia’s automotive industry remains competitive,” Folger concluded.

Pictures: Official Mercedes-Benz release.