The Story Behind Mazda SKYACTIV TECHNOLOGY – Mazda CX-5

When Mazda wanted to build its next generation of vehicles, it took a look at where the rest of the world was heading in terms of development. Top of the pinnacle was the development of alternative energy vehicles, which included the use of the fuel cell, electric vehicles, and hybrids, including plug-in hybrids. Further down the chain, automakers were introducing fuel –saving features such as regenerative braking, idling stop systems, and electric power steering systems to support base engine technologies for better fuel efficiency.

The fuel cell vehicle appears to be the best bet insofar as energy efficiency was concerned, but the high cost of development and the high cost of production indicates that the fuel cell vehicle will not see full commercial application in automobiles for a long time to come. Electric vehicles are relatively easier to develop, but are hugely dependent upon battery development, and at the moment, despite the fact that it has advanced greatly in the last decade, the cost of manufacturing is still relatively high; besides, with the growing consciousness of environmental issues, the disposal of batteries and the rare earth elements present in them is causing some concerns.

Hybrid engines, which are a combination of a conventional engine and an electric motor that work with energy regenerative systems to recover energy otherwise wasted and convert it into electricity to be fed back into the drive system, are the solutions for the day. All the car makers, including Mazda, however, agree that hybrids are at best a stop gap measure that is temporary, and Mazda felt that something needed to be done.

Mazda believed that the ICE, or internal combustion engine still had potential for development, given the fact that even the most fuel-efficient engines of the day still had approximately 70 percent of fuel going out the exhaust as un-burnt gases. Mazda also believed that it was possible to build automobiles as integrated units that as a whole contributed to more efficiency, and so it went into the design of such a vehicle concept with its entire development force as a team working together. At the same time, with a team that is made up of driving enthusiasts (see video on Mazda Zoom-Zoom), it was also important to the team that the driving performance and safety should not be compromised.

|

| SKYACTIV Diesel engine is already developed, but not available yet in Malaysia |

The SkyActiv Mazda CX-5

The Mazda CX-5 is the first generation Mazda to adopt the entire range of the brand’s newly developed SKYACTIV TECHNOLOGY; it encompasses re-engineered engines, transmissions, bodies and chassis, and is the first Mazda to embody the all-new “KODO-Soul of Motion” design theme. Put together, the Mazda CX-5 delivers a never before possible combination of sharp and lively road performance, vehicular safety and environmental friendliness, wrapped in an edgy and tantalising body that looks good from all angles, on the move or stationary.

The usual practice in designing a vehicle is to look at existing models, existing features, and finding ways to improve on the current features, or totally re-designing different parts of the body. For the design of its next generation cars, Mazda decided to start with a blank piece of paper, with the purpose of developing a new approach towards building automobiles based on improving the current ICE to deliver vehicles that can achieve equal to or better than the hybrids of the day.

The design team decided to go against convention, to question the status quo, and tread new ground, asking ‘Why Not?” rather than admitting “It cannot be done”. Although each department (body, engine, drive train and chassis) had to work individually to design its own parts, each was conscious of the needs of their counterparts through regular discussions and exchange of ideas.

|

| The CX-5 is the most technologically advanced in its class |

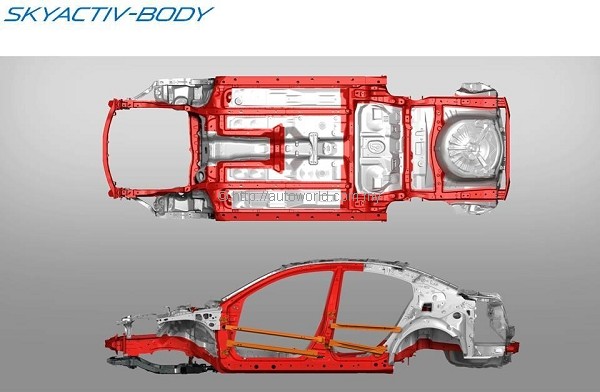

SkyActiv-Body

The Body development engineers needed to have a straight and continuous basic framework to ensure high body rigidity. In a conventional body frame, the front part is usually curved upwards to accommodate the engine and transmission, which works against the body design language.

At Mazda, this was resolved by reducing the size of the engine and transmission. For crash safety, Mazda adopted a concept called “Multi-load path structure” which improves impact absorption by dispersing the load at the time of a crash in multiple directions. By extensive use of high tensile steel (60 percent) and weld bonds to reinforce key areas, Mazda was able to reduce overall weight which contributes to fuel efficiency while improving overall rigidity to attain world-class crash safety performance.

|

| SKYACTIV Body uses high amounts of High Tensile steel which is lighter, but stronger. |

SkyActiv Chassis

The chassis determines a vehicle’s core performance attributes – how it goes, turns and stops. In designing the chassis, Mazda’s top priority was to further emphasize Mazda’s unique driving characteristics, which they describe using the words ‘Light’ and ‘Agile’. However, agility usually comes with a compromise, which is reduced stability at high speed, and sacrificing ride comfort. In developing the SkyActiv chassis, the challenge was to concurrently improve high speed stability and ride comfort whilst improving agility. The main task, according to Mazda, was to improve rear grip, which is needed for better high speed stability and ride comfort. There are two ways to improve rear grip; one is to reinforce the rigidity of the rear suspension and the second is to optimize the tyre orientation to counter the lateral forces they are subjected to. For the SKYACTIV Chassis, Mazda chose to optimize the tyres’ orientation, and by doing so, secure the desired amount of grip despite using softer dampers and springs to ensure ride comfort.

However, improving rear grip also unfortunately works against agility; the problem was resolved using a quicker steering ratio to enable quicker response. Reducing weight also increases agility, but if you simply shed weight, rigidity suffers. This was resolved through optimizing sub-structures, and revamping production methods and materials to achieve the desired results. As a result, the SKYACTIV chassis was 14 percent lighter versus the previous chassis; suspension was reduced in weight, but rigidity was improved by 40 percent.

The SKYACTIV chassis achieves Mazda’s Jinba-Ittai driving pleasure, which balances ‘one-ness between car and driver, ride feel and high speed driving stability.

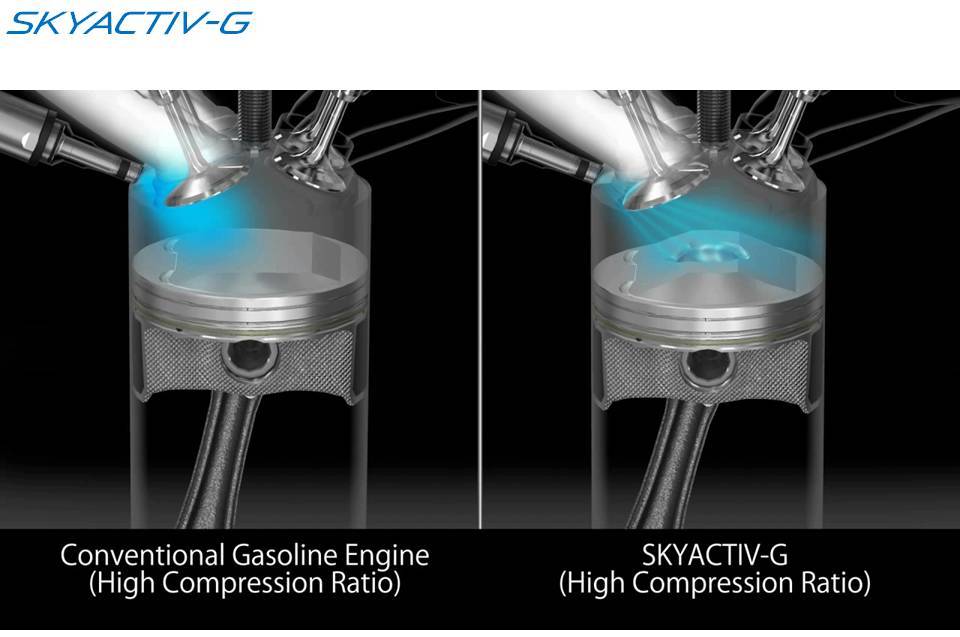

SKYACTIV Engine

The heart of every vehicle is in its engine, and the Mazda design and engineering team again went against known convention to come up with gasoline and diesel engines that defied the norm. The SkyActiv gasoline engine runs a compression ratio of 13:1, and with a specially designed 4-2-1 exhaust system, manages an impressive 114 kW at 6,000 rpm (FWD), 113kW@6,000 rpm (AWD), while generating 200Nm of torque (FWD), 198 Nm (AWD) model of the CX-5.

The biggest achievement is probably the rated fuel consumption (EC Regulation mode basis) of 7.3 L/100km Combined cycle, 6.3L/100 km Extra urban, and 9.1L/100km Urban (AWD 6AT).

|

| SKYACTIV Gasoline engine runs 14:1 Compression Ratio. In Malaysia, it is 13:1 |

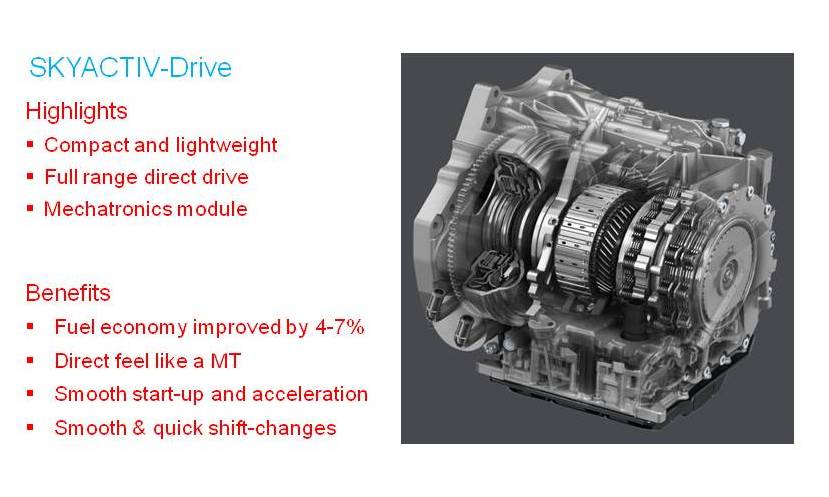

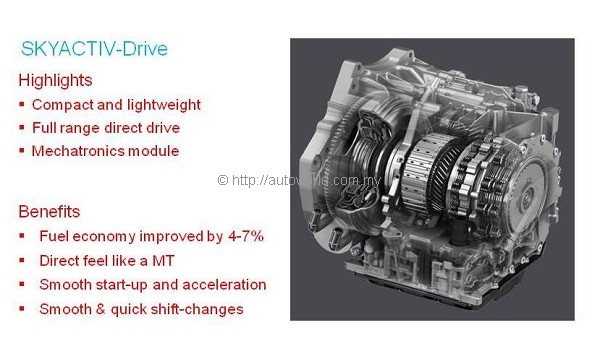

SKYACTIV Transmission

The SKYACTIV transmission combines the advantages of Continuous variable transmissions, Dual Clutch transmissions, and conventional automatic transmissions. The SKYACTIV transmission provides powerful, steady acceleration from standstill, and quick and direct shifting. The key features are its lightweight design, compact size, and a wide lock-up range.

|

| SKYACTIV Transmission combines all the good attributes of a manual, auto, DSG, and CVT |