Continental Automotive Group – Visiting the Powertrain Division

The following day after trying out some of the Continental Automotive Group Interior divisions handiwork at the company’s mini test track in Regensburg, we reconvened at the same site to check out innovations from the group’s Powertrain division.

With sales of some €4.7 billion and over 26,000 employees under its payroll, the Powertrain division on its own has the resources to rival many big companies. In terms of sales volume it is market leader in the making of fuel pumps and injectors (diesel and petrol), transmission control systems, sensors, actuators and e-mobility systems.

The world may be talking about electrification of the automobile, but Continental remains firm that the internal combustion engine will remain as the dominant mode of road beyond 2020 and it is putting its chips down on such a development. Growth will no doubt be seen in the global sales of hybrid and EVs, but chances are you and I will still continue to pump fossil fuel into our cars for a long time to come.

|

| The 1.2-litre EA 111 engine in the Golf. Continental replaced VW’s original charger with its own. |

In the last few years, we are seeing European manufacturers migrate en masse from port fuel injection to direct injection, very often in tandem with turbocharging, for their petrol-engined models. This development is somewhat ironic as it was Europe that rejected direct injection technology when Mitsubishi pioneered it in the 1990s.

Today, with the Germans leading the way, turbo direct injection is the ‘in vogue’ powertrain setup of the continent, and Continental is at the forefront of its development. Already supplying direct injectors to various carmakers, Continental is also now dabbling into the business of turbocharging as part of a collaboration with the Schaeffler Group. Production of the first Continental turbochargers will commence in September 2011 at Schaeffler’s plant in Lahr, Germany.

|

| A turbocharger cutaway. |

At the Regensburg test track, we had the chance to try out a Volkswagen Golf 1.2 TSI with its original turbo removed and replaced by a Continental prototype. This Golf here uses the 1.2-litre EA111 engine which Volkswagen Group Malaysia only offers with the Polo. The test car had manual transmission, and it pulled almost as convincingly as the twincharged Golf 1.4 TSI. On a side note, VW’s habit of over-servoing the brake pedal makes smooth heel-toe downshifting rather tricky.

The other VW test vehicle on the day was a diesel-powered Polo 1.6 TDI retrofitted with injectors from Continental. In its original form, the engine is already good for 104hp and 250Nm, which is plenty for a car of the Polo’s size. According to Continental personnel, they were able to twist out an extra 25Nm of peak torque on top of it. We didn’t have the benefit of a factory-spec vehicle for comparison, but suffice to say that the Polo diesel pulled strongly and smoothly, with speeds of 130-140kph not a problem on the very short straight of the test track.

|

| Volkswagen Polo test car here is retrofitted with Continental injectors. |

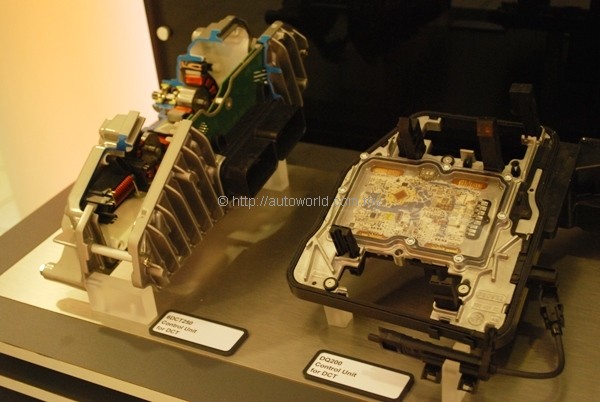

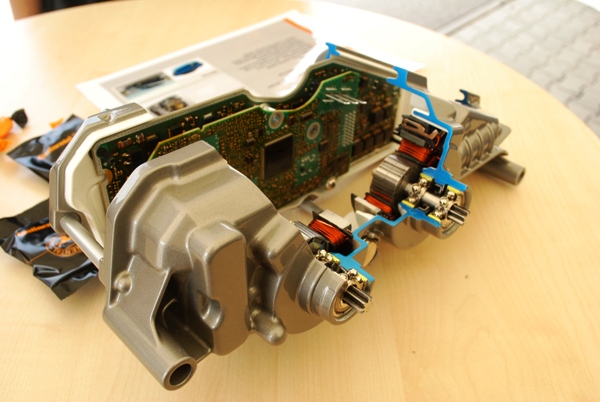

The Powertrain division’s job scope extends beyond just engines to encompass transmissions as well. Although Continental does not build actual transmissions like ZF or Getrag, it is a key supplier of transmission control units to the industry. One notable product developed by Continental in this area is the EAST TCU platform developed for emerging Asian markets as a cost effective solution suitable for use in torque converter automatic transmissions, CVT, dual clutch transmissions and automated manual transmissions.

Although Continental is steadfast in its belief that the internal combustion engine will remain relevant and on the path of growth, it has also not hesitated to diversify its efforts into hybrid and EV powertrains. The company had a hand on the propulsion system of the BMW ActiveHybrid7, which we found to be ridiculously fast for a limo of its size. Right at the other end of the fast scale was a smart fortwo all-electric car.

|

| BMW ActiveHybrid7 |

Looking ahead, Continental is scheduled to start production of an EV drivetrain to an unspecified European manufacturer, we suspect BMW for the new i series city cars, this year. The production volume for this project is expected to reach 50,000 units per year, and more product launches are scheduled for power electronics and motors in Europe and Asia later this year.

Next: We conclude our trip with a visit to the Chassis & Safety division in Frankfurt.