Proton Gen.2

Brand new model powered by a brand new engine coming from a brand new factory. This is definitely one of the most significant milestones in Proton’s history and an achievement which can be said to be on a higher level than the launch of the Waja. In fact, the Waja was probably more of a ‘dry run’ for Proton’s capabilities and with the new Gen.2, Proton is clearly ready to go to battle.

The development of the Gen.2 began in August 2000, around the time the Waja was launched. While Malaysians were excited over the arrival of an entirely new Proton model, the Gen.2 team in Vehicle Program B put together their proposals and presented four full-scale clay models to the management. From the outset, the plan was to have a 5-door model and over 12 months, the chosen design was refined by a team headed by Damien Chia, a Malaysian designer who was challenged by Proton’s CEO to break away from ‘boundary thinking’.

It must have been a dream come true for Damien because he could depart from convention and propose a new styling direction for Proton, just as Chris Bangle has done with BMW styling. With the Gen.2, the stylists took a fresh approach to how surfaces would look and chose deeper concave lines and shoulders for a masculine and aggressive look. That the Gen.2 would be a sporty sort of car meant they could have a narrower focus in the styling since it would be targeted at a specific group of younger buyers.

“It’s a car that has been specifically designed to appeal to young families, in line with Proton’s long-term objective of creating cars to meet with the pre-requisites and expectations of specific target groups,” explained Damien, who is confident that the looks will evoke emotion in buyers.

“What we essentially set out to do was to break from the tradition of building one ‘safe design’ for everyone,” he added. This means that Proton will be niche-oriented and in doing so, be able to provide more appealing products to different segments of the market.

|

EXTERIOR

The present Proton corporate face can be traced by to the Iswara of the early 1990s and in some ways, it is retained but re-interpreted for a new decade. Not forgetting the Malaysian roots of Proton, the stylists drew inspiration from the wau (the Malay kite) and also the handle of the keris when they shaped the front grille. This is the new face of Proton and it is bold as well as distinctive.

“You’ll see this face evolving in appearance, size and presence, depending on the target market of individual products,” said Damien.

Little details count and a lot of attention was given to all areas of the car. For example, the door handles were the subject of many hours of work to produce a classier sort of design which was also functional.

Dimensionally, the Gen.2 is about the size of the Wira Aeroback (which it does not replace, contrary to what has been expected) and it is among the wider cars in its class at 1725 mm. The sleek shape, which has been compared to the Renault Megane but also looks a bit like the Honda Insight, has a Cd of 0.33 and can drop to 0.30 with a spoiler.

The development period for the Gen.2 was speedier than the Waja – 1 million man-hours versus 1.7 million man-hours – because a lot of experience had been gained in developing the earlier model but more importantly, the same versatile platform was adopted. This meant that more time could be spent on the body as the platform was already done and what was needed in that area was tuning.

When it came to body structure, the aim was to achieve the same sort of stiffness as German products (BMW was mentioned). Extensive use of computer aids was made and the result is a bodyshell which is claimed to be very stiff – double that of any present Proton – and able to offer optimum occupant protection. It meets international crash standards and the effectiveness of the design was confirmed by actual crash tests of 15 prototypes in Australia.

The quest for stiffness has meant that the Gen.2 is not a light car and at 1175 kgs, it is 10 kgs lighter than the bigger Waja, and heavier than its rivals. The aeroback design has also contributed to the weight as the large glass sheet at the back is heavy.

THE CAMPRO ENGINE

But the engineers were not discouraged by the weight factor because they would be having a brand new engine under the bonnet and one which was Proton’s own. This is the CAMPRO engine which was the subject of a RM500 million program and involved 200 engineers. The engine program was run concurrently with the Gen.2 program and prototypes were driven over more than 27,000 hours in Sweden, Spain, Australia and of course, Malaysia.

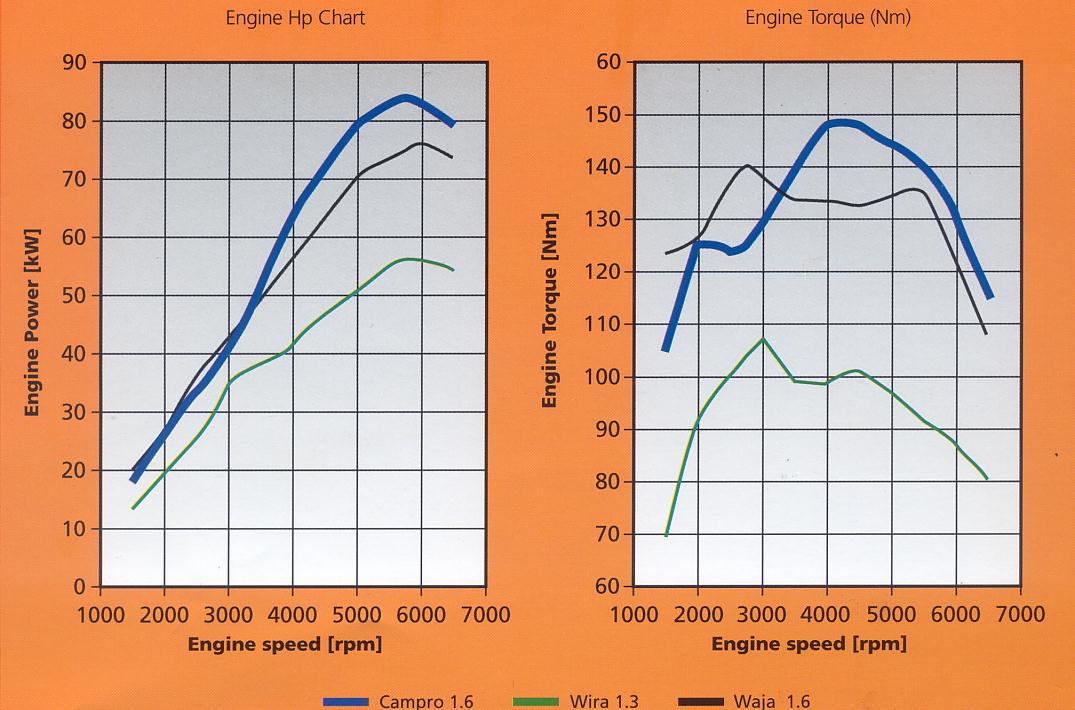

The first representative of the CAMPRO family is coded ‘54PH’ and is a 1597 cc 4-cylinder DOHC 16-valve unit. This long-stroke engine has a cast iron block and has been designed as a modular unit, which means variants can be developed using similar parts such as pistons and blocks, thereby lowering costs. In fact, by having its own engine, Proton is believed to have cut its engine costs by 44%, an important saving to make it more competitive.

The 54PH engine, which is just 581 mm long, delivers 82 kW/110 bhp of power at 6000 rpm and 148 Nm of torque at 4000 rpm on a compression ratio of 10:1. Careful tuning has given it linear torque progression to complement the high-revving character. On paper, it looks like a class leader with a specific power output of 70 bhp/litre of displacement and as Azhari Che Hassan, the leader of the CAMPRO team pointed out, this has been achieved without using a variable valve timing mechanism. So imagine what could be obtained when they offer a future engine with such additional features?

“Actually we have completed development of a more powerful version and it won’t be long before it will join the line-up,” he revealed, adding that it will have the Lotus-developed Cam Profile Switching technology (that is where the CAMPRO name was derived from) which is said to be conceptually like a variable valve timing system. A source said that the power output from the same displacement could be increased by 18% at least.

Performance is one thing but to the average motorists, maintenance costs are also important. In this respect, the engine has been designed for oil change intervals every 10,000 kms, instead of the usual 5,000 kms. Over the longer term, its service life is claimed to be good for 250,000 kms and no major overhaul should be needed for 10 years under normal usage.

Proton’s own engine management system is used and this is the EMS700. It incorporates a diagnostic tool which will enable quicker trouble-shooting and as it is Proton’s own component, there will be the possibility of customizing programming to suit market needs. This is something which Proton has not been able to do with the older models as the engine management system has come from Mitsubishi Motors as a ‘sealed box’ and to ask for reprogramming has been expensive.

Proton did not forget about the environment in developing the CAMPRO engine and it not only meets prevailing Malaysian emission control standards which are at Step-2 but can easily meet the tougher Step-3 and Step-4 requirements which are already applied in Europe. A clean and economical NGV version using gas is also under development and will be offered in the near future, but there are no plans for a turbodiesel.

The Gen.2 will come with manual 5-speed and automatic 4-speed transmissions, the latter to be available only in about two months time. Little is know about these units but they come from Mitsubishi Motors. According to Tengku Mahaleel, making its own transmissions would be too costly for Proton as very high volumes are needed. As there are many specialists in transmissions around the world, it is more cost-effective to buy from them. The extra cost in buying this item from others is not significant but the savings on the engine are: up to 40% savings or RM150 million annually.

CHASSIS

In chassis design, Proton can proudly proclaim itself to be above average, thanks to having Lotus Engineering. The Gen.2 benefits from a chassis that has already been in use for some three years and proven to be a competent platform. It is the same as the Waja’s and even shares the same wheelbase but extensive reworking and tuning has been done so it is not merely a Waja chassis with a different body.

The front suspension uses those universal MacPherson struts with coil springs and shock absorbers, both sides tied by a direct-acting stabilizer bar. Unlike the Waja front suspension, the Gen.2’s has a new dual-path mounting concept to separate the load path of the spring from the load path of the shock absorber. This has meant that instead of a single rubber bushing to support the car and isolate noise, there are now two separate elements to give better impact absorption and eliminating damper lag in extreme conditions.

The rear suspension layout is described as a multi-link arrangement and basically has a transverse link to each wheel coming off a strong subframe under the rear-end. The multiple links hold the wheels in a specific geometry by acting or reacting against different forces during cornering. It looks simple but there’s actually a complex relationship to be managed and Proton’s engineers have enough understanding to make it all work very effectively.

Each wheel has a 15-inch disc brake as standard, and the provision of disc brakes on the rear wheels is something which goes back to the Wira days. The front ones are ventilated while the rear are solid. Factory ABS is available but only on the high-line version which will cost more and be available later on. The ABS includes EBD (Electronic Brakeforce Distribution) which ensures that braking is always balanced between front and rear, whatever the load carried.

|

INTERIOR

Simplicity, stylishness and sportiness were the elements Proton’s interior designers, led by Head of Design (2) Zafruddin Shamsuddin, set out to achieve when they began to create the Gen.2’s cabin. The theme was ‘Lotus Inside’ and this meant that they had to incorporate ‘Lotus DNA’ – essentially a sporty ambience – inside.

It is for this reason that the cabin of the Gen.2 looks light years ahead of the old Proton generation of cars. It starts from the front – the dashboard – where minimalism is apparent and function takes precedence over form. Everything is neatly clustered with audio system and ventilation controls running down the middle section. Circular meters, set deeply, bring the elegance of a chronograph presentation which is typical of sportscars, Installed as standard on all versions is a simple tripcomputer which provides information on average fuel consumption (in litres per 100 kms), distance to empty tank and journey time (from firing up the engine).

Employing SAFEWORK, the latest in 3D and virtual ergonomics software, the interior designers were able to take things to the next level of sophistication. The dashboard itself has been made less bulky, freeing more space for the occupants. However, in the process, the glovebox has been omitted though a wide shelf is available on both sides of the dashboard.

Storage space is best described as ‘modest’ even though Proton says it is generous. There are small pockets in the front doors, a console box between the front seats and a cupholder (which will probably be used for coins), a namecard holder behind the vanity mirror on the sunvisor and a sunglass holder. If there is any area of the cabin which leaves something more to be desired, it would be storage.

To emphasise the sporty nature of the car, the seats have been given a one-piece racing style with a fixed headrest (in the old days, such seats were called ‘tombstone seats’!). They have been designed for good ergonomics and provide support in all the important areas when the owner drives the Gen.2 in the manner it begs to be driven – a spirited manner!

In the basic version (the only one you can get for now), the Gen.2 has seatbelts with pre-tensioners to limit forward movement of the body during a collision. No airbags are offered but this doesn’t mean they are not available. On the extra-cost high-line version, dual SRS airbags will be available so it is a matter of paying more for the extra level of safety, if a buyer requires it.

Measuring 1858 mm in length, the cabin is 33 mm longer than that of the Wira. The use of the Waja wheelbase has meant that people inside enjoy more legroom. According to Zafruddin, the interior space complies with internationally recognized ergonomic standards for cabins, based on global posture statistics. 95% of occupants of average size and up to 1.88 metres (6ft 2 ins) tall will be comfortable in the front seats; 80% of occupants of average size, up to 1.75 metres (5ft 9ins) will be happy in the rear seats and 50% of occupants of average size, up to 1.65 metres (5ft 5ins) will feel comfortable in the middle of the rear seats. As can be seen, the heights are more than the average Malaysian so it is definitely spacious.

The boot volume is 415 litres which is some 22% more than what is available in the Wira Aeroback and the same as the Waja. The boot floor can be extended for longer objects as the backrests (divided in 60:40 ratio) can be folded down and will be completely flat because the seats flip forward. There is some storage space around the boot and under the floor is a compact space-saver spare tyre which is meant only for emergency use.

SECURITY

The Proton Wira has been a very popular model and a best-seller and also No. 1 in the stolen car list. It is inevitable that the most popular models will be much sought-after by thieves and intent on preventing the Gen.2 from gaining this unwanted ‘honour’, Proton has made the new model harder to steal. An engine immobilizer complements the security system which meets the stringent Thatcham criteria. Additionally, the CAPTOR vehicle tracking system is also incorporated so that a stolen vehicle has a higher chance of being recovered. Additional features of the system include a fuel-cut and carjack panic switch.

BUILD QUALITY

Proton has world-class capabilities in design and engineering and no one will argue about that fact. However, the problem that has dragged Proton down, especially in the eyes of the Malaysian public, has been build quality. It hasn’t been performance or design, just the inconsistent quality of the cars being delivered.

In some ways, some of the quality issues are due to the use of older manufacturing processes that date back to the 1980s when the factory was built. Some of the suppliers are also to blame because they make the components and when something like a power window fails, people don’t necessarily blame the supplier (whom they may not even know about) but they blame Proton.

Tengku Mahaleel does not deny that Proton’s cars have faults, a position which differs from that which he had when he launched the Waja. At that time, he believed that the switch to modular assembly would bring about a quantum leap in build quality, besides cutting costs, and in theory, it should have. Well, it would seem that a lot of lessons have been learnt and this time round, he is more guarded in how he talks about quality, even acknowledging that there could be faults in the early builds. This is not unusual and even the best manufacturers will have some problems with early builds of new models.

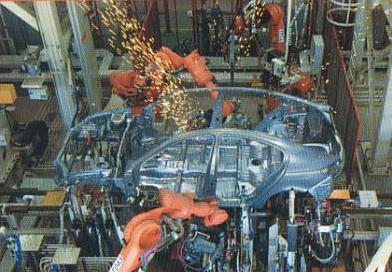

But what is different this time is that there is a brand new factory to build the Gen.2 and this facility has been designed with the latest processes that will bring about higher and more consistent build quality, greater efficiency and higher productivity.

Automation, with some 180 robots, is 60% compared to 30% at the Shah Alam plant. Complementing this increased level of automation is a 3-stage line inspection process for quality assurance. The first is static evaluation on fitting and appearance of exterior and interior areas of each car as it comes off the line. This is followed by a dynamic evaluation on the function and driveability, after which there is a final inspection before the cars are deemed ready and fit for delivery to customers.

“Even then, our process to ensure that a high-quality car reaches the customer does not end,” he said. “Besides the usual Pre-Delivery Inspection (PDI) procedure at every dealer, we have formulated a 120-point form which a customer will go through with the salesman at the time of delivery. Only when the customer is satisfied should he or she sign this form.”

Responding to problems more quickly has also been promised and the job of resolving problems is being given to regional heads. No longer should there be delays due to the lengthy process of referring everything to the head office. Special technical teams have also been established which will be sent to any dealer who has cars with difficult problems.

Incidentally, besides the extra-long factory warranty, the Gen.2 also comes with a 10-year anti-corrosion warranty, thanks to the use of galvanized steel in many areas and advanced anti-corrosion treatments at the new factory. Of course, customers will be required to periodically present their cars to an authorized service centre for inspection in order to keep the warranty valid.

THE FINAL WORD

The Gen.2 is clearly a car that is very different from past mainstream Protons, with the exception of the Waja. It is the first of a family of cars which will number at least 20 during this decade (another two are due this year and they will be even more exciting). No longer having to clone models of other manufacturers and no longer having to depend on others for the ‘heart’ of the car, Proton is ready to face the competition on a level playing field.

“Suffice to say that with our new and diverse range of models to come, people will have difficulty believing they are Protons. If there was a problem in the perception people had of Proton cars in the past, it was that our products were essentially evolved from Mitsubishi products. As we move away from such an association with Mitsubishi products, we will need that ‘wow factor’ in our own products to clearly establish Proton as a brand in its own right,” said Tengku Mahaleel. “With the new Gen.2, we are out to do not only that but also make a lasting impression.”

GEN.2 PRICES (without insurance, P. Malaysia)

GEN.2 1.6 MANUAL – RM52,888

GEN.2 1.6 AUTOMATIC – RM55,888

|

The movie – View the 360 degree Interior