100 Years of Bringing Engines to Life

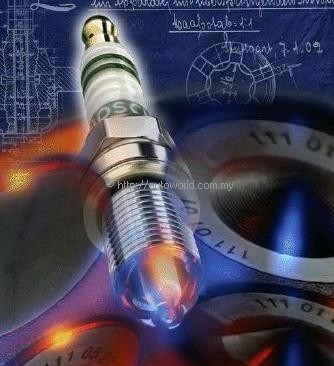

One component in the petrol engine literally gives it ‘life’ and that is the spark plug. While petrol is also essential, without the all-important spark, the combustion process cannot get started. At the critical moment, the spark ignites the volatile air-fuel mixture which explodes and generates energy to force the piston back down, creating power to propel the car.

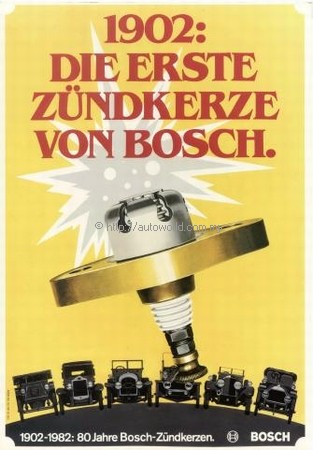

However, the spark plug as we know it today was not invented at the same time as the internal combustion engine. Other solutions were used until 1902 when Robert Bosch invented the first spark plug which was actually a rather large thing and was referred to as a ‘high-voltage magneto’.

Over time, the spark plug became compact and took the form we recognise today on top of millions of engine cylinder heads. And while it may seem to not have undergone any changes, the spark plug has actually evolved in many ways in terms of materials used and sparking methods.

Back in the early days of the motorcar, engines were relatively simple but the combustion process was not as efficient as it is today. There were no regulations concerning toxic emissions in exhaust gases and incomplete combustion meant that a lot of particles were created inside the combustion chambers. These particles would collect on spark plugs and reduce their efficiency, thus limiting their service lives.

Over the decades, engines got better, more powerful and electrical systems also improved. Having a strong and hot spark – which can range from 30,000 to 100,000 volts – leaping across the tiny gap between electrodes at the tip of the spark plug is important to getting proper and complete combustion. Accumulation of deposits, especially the carbon which is a by-product of combustion, on the spark plug would affect the strength of the spark so systems were developed to boost the spark strength.

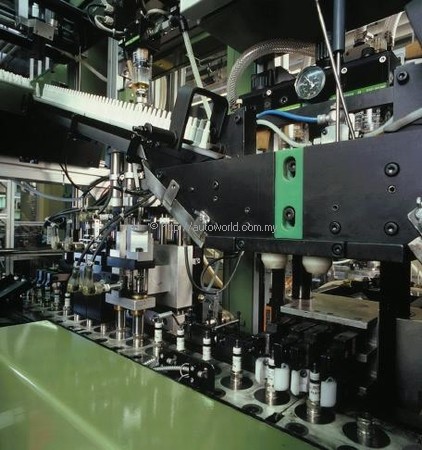

As the world leader and pioneer in spark plugs, Bosch has obviously vast experience in making these components perform better. The company has made over 7.5 billion spark plugs to date and presently makes around a million spark plugs a day at four of its 227 factories around the globe.

Most motorists may not realize that Bosch has some 1,250 different types of spark plugs for all kinds of applications (not just cars and motorcycles) and increasingly, individual carmakers are presenting unique specifications for the spark plugs in their engines, so more variations are needed. In all, it has made more than 20,000 types of sparks plugs in 100 years.

“The trend is towards longer service life and where it was acceptable with 50,000 kms, now we have manufacturers telling us they want not less than 100,000 kms for spark plug life and in years to come, even more than that figure!” said Rudolf Seethaler, Regional General Manager/Southeast Asia for Robert Bosch (SEA) Pte Ltd.

To meet such challenges, Bosch has developed high-performance products like the Super 4 spark plug which uses the surface air-gap principle for superior spark generation. This spark plug is unique with four peripheral electrodes surrounding a silver-plated centre electrode and is claimed to give 60% greater sparking efficiency.

This means less fouling – in fact, the spark plug ‘cleans itself’ too – and therefore almost no misfiring. The consistent and strong spark possible will result in better combustion and smoother engine operation, all of which add up to more enjoyable motoring for the driver.

The surface air-gap concept is one of many approaches to achieving higher spark strength and quality. Some manufacturers have grooves cut into the electrodes or extra electrodes but the most common is the ground electrode from the side curved over the centre electrode. Bosch has some 26 different electrode configurations at the moment.

continued on page 2