Malaysia is taking decisive steps towards becoming a regional hub for electric vehicles (EVs), with the official launch of Proton’s first dedicated EV assembly plant. The facility, located within the Automotive High Tech Valley (AHTV) in Tanjung Malim, was inaugurated last week by Prime Minister YAB Dato’ Seri Anwar Ibrahim.

The milestone plant is the first of its kind in Malaysia, designed exclusively for producing EVs, with a scalable capacity of up to 45,000 units per year. It begins operations just 7 months after its groundbreaking ceremony on 7 February 2025, reflecting the speed and scale of PROTON’s electrification push.

The Proton e.MAS 7, Malaysia’s best-selling EV since its launch in December 2024, will be the first locally assembled model produced here, followed by the Proton e.MAS 5 (which is planned for market launch soon). Through PROTON’s collaboration with Zhejiang Geely Holding Ltd, premium EV brands such as Zeekr are also planned for local assembly, further positioning Malaysia as a central hub for regional EV exports.

Present at the launch were Perak Menteri Besar YAB Dato’ Seri Saarani Mohamad, Minister of Investment, Trade and Industry YB Tengku Datuk Seri Utama Zafrul Tengku Abdul Aziz, Transport Minister YB Loke Siew Fook, and Minister of Science, Technology and Innovation YB Chang Lih Kang. They were joined by Tan Sri Syed Faisal Albar, Group Managing Director of DRB-HICOM and PROTON Chairman, Geely Chairman Li Shufu, and Proton CEO Dr. Li Chunrong.

First Phase Investment For Scalable EV Growth

The RM82 million plant sits on a 5.57-acre site, with today’s RM47 million first phase delivering an annual capacity of 20,000 units. Designed with scalability in mind, production can be ramped up to 45,000 units per year to meet future demand in both domestic and export markets.

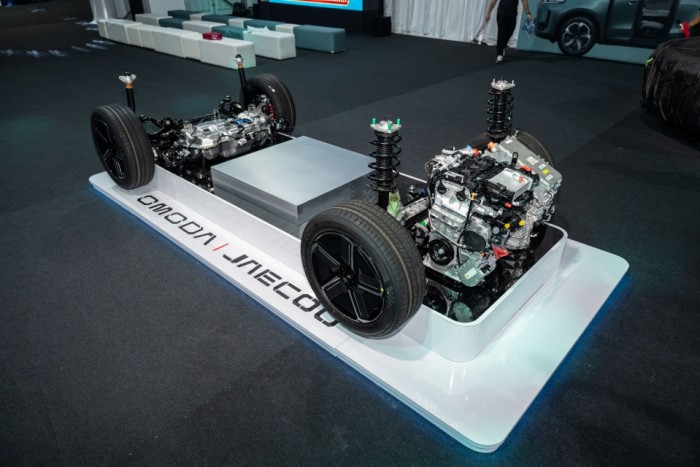

Equipped with advanced production technology from Geely, the facility integrates automation with skilled local talent. Key equipment includes specialised chassis and sub-assembly lines, EV electrical testing systems, and advanced quality control mechanisms.

The plant has already recruited 30 trained operators for full-scale operations, with over 200 new jobs expected to be created in the coming years, helping to develop local expertise in EV manufacturing and industrialisation.

“The launch of this state-of-the-art EV plant marks a historic milestone for PROTON and Malaysia’s automotive industry. This facility, built with advanced technology and a focus on scalability, will be the backbone of our commitment to producing world-class electric vehicles. The Proton e.MAS 7, which has already been embraced by Malaysian consumers, is just the beginning of our journey towards a sustainable future,” said Dr. Li Chunrong, Chief Executive Officer of Proton.

Railway Logistics Hub To Support AHTV Efficiency

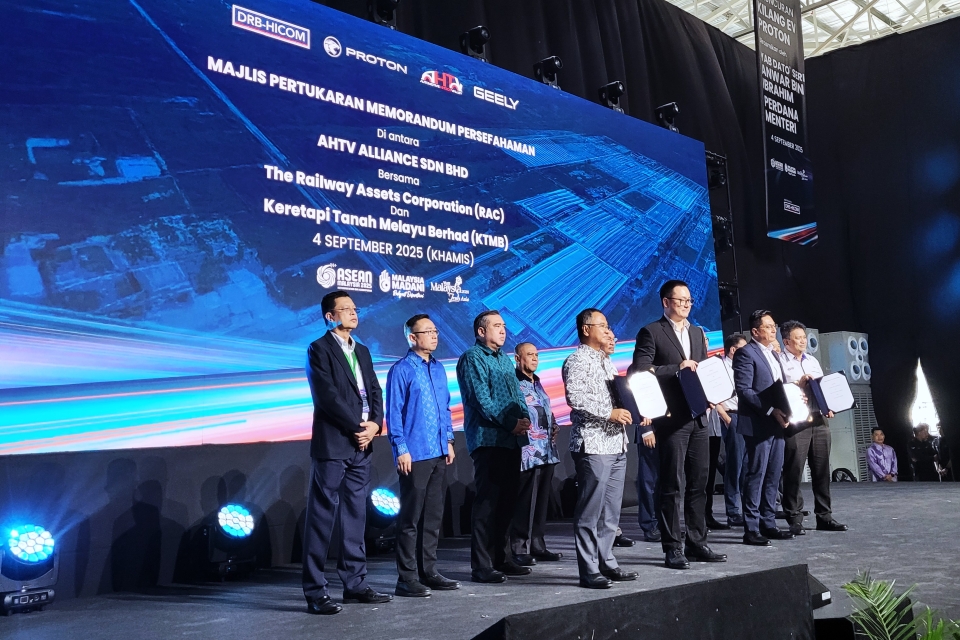

To strengthen AHTV’s ecosystem, AHTV Alliance Sdn Bhd (AASB) signed Memorandums of Understanding with Railway Assets Corporation (RAC) and Keretapi Tanah Melayu (KTM) to study the establishment of a railway logistics hub.

The railway hub is aimed at boosting logistics efficiency by moving containers via rail instead of road, in line with the Ministry of Transport’s goal of increasing rail-based cargo transport. More importantly, the use of a railway system for logistics will reduce the number of heavy duty trucks plying highways and roads thus reducing the chances of accidents that could disrupt the supply chain as well as traffic flow.

It will also support AHTV’s focus on sustainable development and help attract further foreign investment into the EV sector.

Designated as a high-impact project under the 13th Malaysia Plan, AHTV is envisioned as a catalyst for next-generation vehicle manufacturing in the region. With Proton’s new EV plant as its anchor, Tanjung Malim is poised to become Malaysia’s gateway to the regional EV supply chain.