Toyota Idea Expo 2003

Each year, around the time the leaves turn golden brown and start to fall in Japan, a very unique event takes place in Toyota City which sees unusual machines providing mobility to humans. It’s the Toyota Idea Expo and it has been organized by the Toyota Engineering Society (TES) since 1976.

This year’s event was the 28th and was expanded to include a few other activities, all under the banner of “Overcoming Challenges, Realizing Dreams”. Speaking to the participants, Toyota’s Executive Vice President Dr Akihiko Saito, who also heads TES, emphasized how the event’s personal approach to monozukuri (making things) promoted genchi genbutsu (hands-on experience), one of the practical pillars of Toyota’s manufacturing philosophy.

Anyone who is a member of the TES can participate in the Idea Expo. Members gather outside of working hours to brainstorm, design and build their inventions. About two and a half months are allotted for vehicle construction, beginning in mid-July. Vehicles are judged on their concepts, technology and potential for commercialization. After Expo, vehicles are ordinarily dismantled. However, this year, at least one was sold to a member of the audience for 1,980 yen (about RM70).

The idea behind the Idea Expo is to let people dream freely and then turn a concept into a working vehicle. It is the same spirit that drove Toyota’s founders to create their first motor vehicles so many decades ago. It is the spirit of monozukuri, or making things. The Toyota Production System, or TPS, is designed so that “making things” stimulates problem solving through hands-on experience. This is why some Toyota people refer to TPS as the Thinking Production System. If Idea Expo 2003 is any indication, Toyota is well prepared for the future with sharp thinkers capable of generating a bounty of innovative ideas.

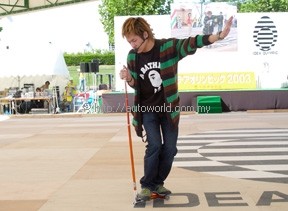

There were 350 entries this year, of which 25 were displayed and demonstrated. The grand prix “Chairman’s Award” went to the ‘Trick Stick’, created by a 9-person team from Toyota’s Power Train & Chassis Components Production Engineering Division, led by team leader Koji Suwa.

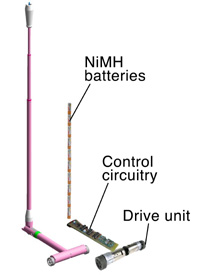

This is how it worked: Hold the stick’s T-shaped handle and it serves as a cane to support walking. Fold the upper part at a right angle and turn the stick upside down to configure a 3-wheeled scooter. The cane’s tip then becomes a joystick controller for steering and pushing the entire stick forward controls the speed. Even with its NiMH batteries, the amazingly slim unit weighs a mere 2 kgs. It uses pulse-width modulation, just like the Toyota Prius hybrid car, to enable independent control of the two drive wheels for smooth turning and acceleration. Coasting downhill, it can even recharge its batteries by regenerative braking. Remote control is possible via a cellphone… in case you need help transporting luggage.

Winning the gold award was the “I-Waver,” a futuristic scooter that provides a wave-riding feel on solid ground. A single barrel-shaped wheel with integrated motor permits side-to-side rolling and front-to-back rocking motion, while a gyroscopic balance mechanism helps keep the vehicle fairly upright and on course. As on a jet ski, the rider can stand or sit – the handle is hinged at the tip of the vehicle. The I-Waver was created by a four-person team headed by Shuichi Ozaki of the Lexus Vehicle Evaluation & Engineering Division.

The silver-award winner was the “Yoyo de Go!”. With a rowing motion, the driver pulls on a hinged lever linked by a rope to two spools on the rear wheels. Each spool is coupled to a wheel by a one-way clutch and loaded by a large rubber strap so that it reels in the rope released when the driver leans forward. Gears enable independent left and right wheel rotation to minimize turning radius. Hiroyuki Hibino’s 12-member team from Toyota’s Power Train & Chassis Components Production Engineering Division created the vehicle.

“Step Board,” the bronze award winner, offers a colorful flying saucer-like surface on which the driver stands, holding onto a central shaft for balance. There is no steering wheel. Instead, the driver steps toward the periphery, causing contact with the road surface and engaging the electric motor drive mechanism to propel the vehicle in that direction. The vehicle is the creation of a 15-member team headed by Masahiko Tanikawa of the Vehicle Evaluation and Engineering Division 2.

An additional Chairperson Award from the TES head went to the “Just in Use,” a vehicle system comprising multiple modules that can be driven independently or interlocked for multi-person transport, created by Takashi Shiomi’s eight-person team from the Vehicle Planning & Production Engineering Division created the versatile vehicle.

A separate contest challenged contestants to build “battle cars” able to successfully carry a polystyrene foam egg down a 30-metre obstacle course starting from a height of 4 metres. The contest required vehicles to jump and make their way through a water hazard, among other impediments – without dropping their egg. “Go Go Egg” attracted approximately 250 entries from throughout the Toyota Group to regional elimination rounds, which narrowed the field to 80 participants who competed in the final time trials.

Children participating in the “Handing Down Technology” workshops built their own battle cars based on a kit and raced them through the ‘Go Go Egg’ course. The workshops were designed to give youth a chance to experience the excitement of making things first-hand.