The CVT in the Honda City

Until recently, most Malaysians would have known of only two types of transmissions in cars – manual and automatic. The CVT – which stands for Continuously Variable Transmission – was less well known although those who had an interest in cars and read the magazines would have known of its existence.

However, in Europe, the CVT has been familiar for quite some time, especially in Holland. Although there is a record of a CVT being invented and patented in the late 19th century, it was in the 1950s that a Dutch company called DAF introduced a car with a CVT that it called ‘Variomatic’, allowing it to be promoted as ‘the car with a hundred gears’ because it had an infinite number of ratios. The founder of DAF, Dr Hub van Doorne, patented the invention and while it may have seemed pointless back then, the foresight is paying off today as many manufacturers are using CVTs.

The Variomatic never made an impact on the automotive world partly because DAF was a small company and even when the company was bought over by Volvo, the CVT was never promoted heavily. Those who understood its concept enjoyed driving it but many more associated it with automatics which were too power-robbing (which was a misconception).

The misunderstood Variomatic also had a strange feel – often described like a slipping clutch – and because of its construction with the belt drive, it was sometimes treated as a joke (‘rubber band transmission’ was a popular one!). So until the 1990s, the CVT never had much attention from leading carmakers since consumers never showed interest either.

In the past 5 years, things have changed and there is a lot of interest in CVTs. It was always known to be a fairly efficient type of transmission, with less power loss than a conventional automatic, and with electronic control systems so sophisticated, it has been possible to refine CVT operation and enhance its efficiency.

Honda is among the companies which has decided to make CVTs a key feature in its cars. Being the innovator that it is, the company has paid a lot for the rights to have a CVT and has added its own advanced technologies to make it better.

Unique transmissions are not new to Honda as many years ago, it had an automatic transmission called the ‘Hondamatic’ which was the first automatic transmission for motorcycles. This 2-speed transmission was later also used in some of its cars models and was a simple unit that offered convenience for those who wanted it. It worked well but with other companies offering 3-speed and then 4-speed units, the Hondamatic was never developed further.

Instead, Honda took great interest in the CVT and introduced a CVT-equipped car in 1995 for the first time. The CVT was known as the Honda Multimatic and was progressively offered in other models, including the Insight Hybrid. Much effort has gone into the development of CVTs because this transmission system is now recognized as being very efficient. In fact, the efficiency of the CVT can be illustrated in a little known exercise which was carried out by the Williams-Renault F1 team ten years ago. They tried running a CVT in the 800cV racing car and in spite of minimal development work on the transmission, there was a 1 second quicker lap time per lap with the CVT.

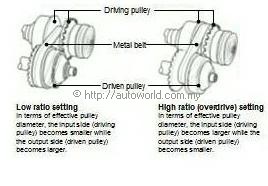

Understanding the way a gearbox works is not easy but understanding how a CVT functions is actually easier because it is a very simple concept. There are two circular cone-shaped wheels (pulleys) which are linked by a metal belt (in earlier years it was a rubber belt); one pulley is attached to the crankshaft and as it spins, power is transmitted to the other pulley via the belt. The two pulley widths, adjusted by oil pressure, react to the position of throttle, speed, and other conditions. For instance, when the accelerator is depressed, the driving pulley width increases. At the same time, the driven pulley width decreases – this results in a “lower gear” effect in a conventional transmission and enables the car to get stronger acceleration.

To side-track for a moment, the reason why different gear ratios are needed is because an engine develops its power over a narrow range and in order to extract the power optimally, you need to use gears to multiply the output. If you ride a bicycle with a single gear up a hill, you will understand this point: a large (lower) gear will require more effort and will be tiring but a smaller (higher) gear will reduce the effort although you have to pedal more. That is why racing bicycles have many gears to choose from so you can get the right combination for a given situation.

However, with the CVT, there are no physical gears so it is not a gearbox at all and is basically a ‘ratio-changer’. The stepless concept allows for an infinite number of gear ratios, overcoming the limitations in conventional transmissions where you can install only so many gears and have to make some careful choices on how to spread them out.

The steel belt is, of course, a crucial item and working with Hitachi Metal, a materials specialist, Honda has come up with a long-lasting CVT belt. The belt is made from two twelve-layer rings and hundreds of elements, which makes it extremely silent. It is durable, highly flexible and easily accommodates the constantly-changing width of the pulleys. Power is efficiently transferred without any slippage.

Unlike conventional automatic transmissions, there is no torque converter and the Honda CVT uses a special multi-layer clutch. Additionally, various proprietary equipment were added in order to make a step-less transmission with high reliability and durability.

There is also an oil-pressure-based multi-layered acceleration clutch which prevents the engine from stalling and allows for extremely smooth acceleration. This clutch allowed Honda engineers to work in a “creep” (an automatic has ‘creep’ unless you apply the brakes) which most automatic transmission users have grown accustomed to.

By putting the acceleration clutch on the “driven” pulley, the “driving” pulley can remain spooled, allowing for quick engine response and making driving in traffic very easy. Also, the clutch is designed to cut off reverse input from the tyres so that the engine does not turn while the car is being towed.

With two types of pulley pressure (high/low) controlled through a 4-way valve, the CVT allows for a wide range of controllability. The low pressure controls the metal belt’s transfer efficiency, and the high-low pressure differences control the continuous shifting. Apparently, this innovative design is unique to Honda’s CVT.

In order to keep the transmission compact enough for use with a front engine car, the forward/reverse switching mechanism and the acceleration clutch are faced toward each other in the pulley space, taking up considerably less space. Furthermore, the input axle is constructed in one unit with less moving parts – allowing for more power to be transferred to the road.

In the absence of the torque converter is a sandwich of two flywheels – resulting in dual-mass flywheel for the CVT. The harmonic resonance was lowered to below idle, shutting out unwanted vibrations caused by the engine’s twisting force generated during torque rate changes. This design allows the CVT to be connected directly to the engine, resulting in less slip-loss, which translates to higher fuel economy.

Electronics play an important part in the Honda CVT, something which CVTs of earlier years never had the benefit of. Tiny but powerful microprocessors are now available for automotive use and can be programmed with a lot of data and for the Honda CVT to have pre-determined switching points of speed, throttle position, and ideal engine rotation, a 3D ‘map’ is programmed into the engine management computer. The difference between current and ideal engine rpm on the chart is continuously fed back to the computer and using linear solenoids, the 4-way valves controlling pulley width are activated, allowing the CVT to make adjustments as needed.

Driving styles are also pre-programmed, and three shifting map options are installed as a switch on the “D” selection: D mode is for normal driving conditions; S mode allows the driver to redline the engine for sportier performance; and L mode allows for engine braking.

The acceleration clutch’s power transfer amount is controlled via the clutch piston’s oil pressure. The “creeping” function is also variable according to the position of the brake pedal. When the brakes are on, the “creeping” goes into fuel economy mode, and when released, will allow for normal “creeping”.

A recent innovation has been the inclusion of a ratio-hold feature which provides some semblance of a manual shift mode. Known as Steermatic, this feature makes use of thumb buttons on the steering wheel to select between 7 pre-determined ratios and hold them for a sporty driving feel. The ratios are selected sequentially like a tiptronic system and to avoid engine damage, if the engine speed hits the redline, the next higher ratio is automatically selected.

Honda engineers love the CVT (also called ‘Multimatic S’ in some markets) because from the technical point of view, it is a very efficient transmission and superior to conventional automatic transmissions using torque converters. The 3D map control pattern allows the CVT to stay in the same powerband if or when needed. For example, it can remain in the high-rpm powerband from a standstill to high-speed, with full throttle acceleration equivalent to manual transmission.

The CVT allows the engine to remain in its optimal power range, resulting in superior fuel economy. Compared with conventional automatic transmissions, there is zero-slip, which means no power loss. With the stepless gear ratios available, shift shock and the drastic jolting during lower gear acceleration are eliminated, leading to a stress-free, smooth driving experience.