SPECIAL TECHNOLOGY FEATURE: HONDA i-VTEC

Cutting Edge Technology for Performance, Economy and Low Emissions

|

For engineers who have to design and tune engines, there are some important considerations to meet and the challenge is balancing them. Motorists usually expect high performance and at the same time want the engine to be economical to run. Government regulations in most countries also require engines to emit low levels of toxic gases to protect the environment.

Generally, it is possible to design engines which can offer high performance but perform poorly in town driving, or engines with lower performance and very economical… but at high speeds, there is insufficient ‘breathing’. Having high performance and high fuel economy together in one engine – plus driveability in all speed ranges – is the biggest challenge for the engineers.

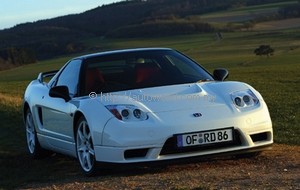

Normally, the engineers will tune an engine’s character according to the type of car it is. For example, the engine of a sportscar would have emphasis on performance at high speeds but it may not be as pleasant to drive around town. The driver would have to rev the engine a lot and consumption may be high. Alternatively, an engine tuned for economical operation will not run well at very high speeds.

In the late 1980s, Honda Motor Company made history in the automotive world when it introduced the VTEC concept for its engines, much of this technology having been developed with the years of successful F1 racing experience. VTEC stands for ‘Variable Valve Timing and lift Electronic Control’ and refers to the feature which enables the variation of the opening and closing of the valves to optimise the flow of air and fuel at all speed ranges.

With VTEC, it is almost like having two different types of engines in one, so to speak: a driver can enjoy stronger high-end performance while in city driving, it is also possible for the same engine to offer more economical characteristics. Output is high and so is torque and with better and more complete combustion, the level of pollution from the exhaust gases is also lower.

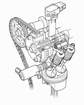

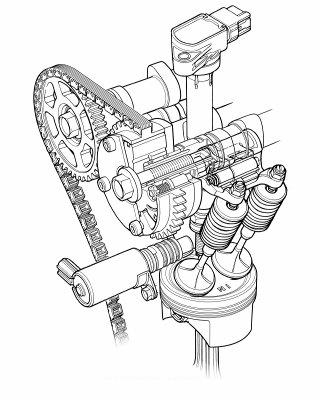

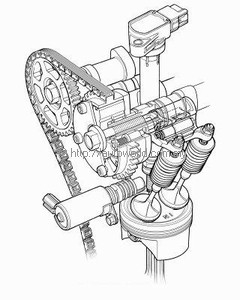

Conceptually, VTEC engine would seem to require two different camshafts, one for high-end performance and the other for low-end performance. This is normally how engineers would approach the problem of meeting such differing requirements although other factors such as gear ratios and vehicle weight also have their influences on overall performance.

|

With the VTEC concept, it is possible to have two different camshaft profiles on the same shaft to suit different driving requirements. At low engine speeds, the valves are opened to ensure good cylinder filling of the air-fuel mixture. As engine speed increases and more and air and fuel is needed, the engine’s computer changes the duration of valve opening to ensure that the increased amount of air and fuel is able to go inside the cylinders.

Yes, it all sounds complex but it is a proven mechanism which has been used in a wide variety of Honda models since the late 1980s. It is so effective that even the two hybrid-engined models – the Insight and Civic Hybrid – have VTEC mechanisms. Depending on the model and its character, the VTEC tuning varies.

For example, on the NSX sportscar high-performance engine, the VTEC shift from the low rpm cam lobe to the high rpm cam lobe occurs at nearly 6,000 rpm! With Honda’s high-performance sportscars, the transition from one cam lobe to the other is very noticeable, accompanied by a surge in acceleration and a sporty growl from the exhaust. However, on models like the Civic, the transition is so smooth it is barely noticeable.

|

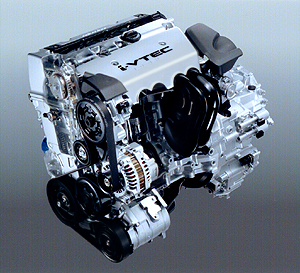

VTEC has already been highly respected among enthusiasts and is today available in the engines of most Honda models. However, advancements never cease at Honda and in recent years, Honda’s engineers have been looking at taking the concept further with additional refinements and features. This has led to a more advanced version of the VTEC concept which is known as i-VTEC and incorporated in the latest 2nd Generation Honda CR-V as well as the new Stream 2.0 which was voted ‘Car of the Year’ in Japan.

|

If you thought the normal VTEC was remarkable, i-VTEC will prove even more impressive! The ‘i’ brings to the VTEC concept “intelligent” combustion control technologies that optimize fuel economy, boast cleaner emissions and achieve higher performance. Incorporating VTC – Variable Timing Control – which continuously adjusts the intake valve timing to best match the current engine load, the driver enjoys abundant low-rpm torque, exhilarating high-rpm power and outstanding fuel efficiency.

With the i-VTEC system, there is a new camshaft to make it possible for continuously-variable camshaft phasing across the engine’s entire power band. During typical operation, the intake camshaft timing is almost fully retarded at idle to help provide more stable idling while reducing exhaust emissions. As the engine speed increases, the intake camshaft is advanced, opening the intake valve sooner and providing additional valve overlap.

This results in increased fuel economy (by reducing pumping losses) and a further reduction in exhaust emissions (by creating a large, internal exhaust gas recirculation effect). Also, to generate additional power throughout the rev range, the intake camshaft is continuously varying the amount of advance or retard, adjusting in a split second to provide additional power when needed.

|

The i-VTEC system in the newly-developed 2.0-litre engine of the latest Honda CR-V contributes to the generation of an impressive 115kw (156 ps) of power at a peak of 6,500rpm and a muscular 190 Nm of torque which peaks at 4,000rpm. And with i-VTEC, the engine’s low to medium power range has improved greatly compared to the previous CR-V’s powerplant.

Development of i-VTEC engines will continue, with expansion to the entire Honda 4-cylinder automobile lineup worldwide planned by 2005. Honda also is using the new i-VTEC concept as a springboard to enhance the speed, efficiency and flexibility of the company’s powertrain manufacturing capabilities.

That Honda has come up with an advanced and innovative concept like i-VTEC is hardly surprising since the company is the largest engine maker in the world, producing more than 11 million engines annually for its own products as well as for sale to other manufacturers.

For more on Honda products and technology, visit the Honda Malaysia website at www.honda.net.my