From Australia to Malaysia

The TD2000 was originally developed in Australia in the mid-1980s by an entrepreneur and car dealer in Sydney, Ross Marshall. He saw great potential in producing a sportscar with the emotive styling of yesteryear and combining it with modern automotive technology. A fan of the British MG cars, he chose the TD series as the basis because it was a significant model in the marque’s history; some 30,000 were built in the 1950s, making it the MG built in the largest volume.

To produce a replica of the car, Marshall acquired equipment from a company in America which had bought over the original dies and jigs for the car from MG many years earlier. The American company had made only 12 replicas and sold them in the USA.

Marshall’s plan was to make around 12,000 units of his replica sportscar – christened TD Sports 2000 – over a 12-month period and sell them through the Nissan dealer network in Australia. A quarter of production was meant for Australia and Southeast Asia while the rest would be exported worldwide.

The Nissan connection was because he had chosen to use a Nissan engine for the car, deriving it from the 1985 Pulsar. Though the Pulsar’s engine and transaxle had been designed for front-wheel drive application, Marshall got assistance from engineers of the Australian Nissan motorsport team to adapt it to rear-wheel drive so that the TD Sports 2000 would be true to the car it was being based on. In fact, he wanted his car to be a very close replica to the MG TD, altering only areas that were necessary due to modern safety regulations as outlined in the Australian Design Rules (ADRs).

First prototype

In early 1986, Marshall proudly unveiled a prototype of the TD Sports 2000 at the Melbourne Motorshow and by April that year, he announced that a prototype had successfully completed safety design testing in California and durability testing near Alice Springs (Australia). Unfortunately, Marshall’s business venture was unable to continue after the middle of the same year due to financial problems but the TD Sports 2000, as a project, did not end.

Instead, Westmex Ltd (a large Australian company in paper, stationery, shoe manufacturing and retail) bought over the assets and rights of Marshall’s company and seriously aimed at turning the TD2000 into a production reality. Those who had scoffed at the project when Marshall’s efforts failed were surprised to see the TD2000 appear again at the 1988 Sydney Motorshow. By then, it was a fully-engineered classic sportscar and Westmex had gone to the extent of establishing a special subsidiary, Australia Classic Cars, to market it.

But getting it to a state ready for volume production and sales took much time, effort and money; in all, Westmex spent no less than A$18 million on R&D over a 2-year period. Marshall had conceived the concept and shown that it could be done but Westmex needed to do a lot more before it could be sold.

For starters, it was decided that the engine would be changed to the one used in the Nissan Pintara (a rear-wheel drive sedan made in Australia). Most of the TD2000’s components would be sourced in Australia and the Pintara’s 2.0-litre 4-cylinder CA20E engine was also made at a Nissan factory in the same country.

Engineering challenges

There were many engineering challenges and one of those was the windscreen wipers. To comply with the ADR safety requirement, Marshall’s prototype had four rather small windscreen wiper blades. This was changed to three blades and the task of making the switch was not as easy as it sounds. The windscreen height had to be raised by 17 mm and careful studies of the swept areas were needed to meet the ADR requirement which stipulated that a given windscreen size had to have a minimum area wiped.

Westmex decided that the 12,000-unit target for the first year was too ambitious and trimmed it to 400 for the initial annual run. But the company was very optimistic about its future when the car was unveiled in Sydney in 1988. However, Westmex suffered severely when the property market, which had been booming, went bust in the late 1980s and by 1990, Australia Classic Cars was wound up.

The company which had been commissioned to manufacture the car, A.F. Gason Pty Ltd, decided to keep the TD2000 alive, partly to recoup losses incurred when Australia Classic Cars ceased operations. Gason put together 100 cars which were sold through its marketing subsidiary, TD 2000 Pty Ltd. However, Gason decided that it would be more lucrative to focus on its core business – making agricultural equipment – and offered the company and its rights to the car for sale.

New owners

The two proprietors of Zaps (Australia), a company which manufactures household appliances, were keen on acquiring TD2000 Pty Ltd, mainly because they were car enthusiasts. They moved the production facility to a new site where the assembly process was refined to achieve a top-class finish. By then, the Nissan Pintara was history, as was the production of the Nissan CA20E engine. TD2000s were thus built with used engines which were reconditioned at the factory before installation.

Under the new company, the TD2000 had greater publicity; enthusiasts were drawn to it not only because of its classic lines but also because it was the least expensive hand-built car available in Australia.

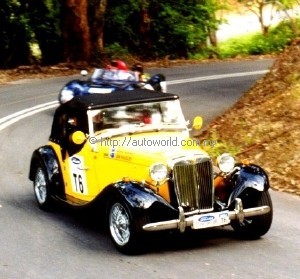

Its toughness was also proven in 1995 during the 5-day Targa Tasmania Rally where it finished first in its class. During that event, the fibreglass-bodied car was up against 300 rivals that ranged from vintage models to the latest Ferraris. Some sarcastic rivals suggested that the TD2000 should have started with the vintage class but it was classified as a ‘new model’ and pitched against cars like the Mazda Miata MX-5 and Toyota MR2!

TD2000 Pty Ltd also offered restoration and maintenance services for classic sportscars. It was a modest business concern which allowed the TD2000 to continue in production.

continued on page 2